How to choose solid surface colors

Not all solid surfaces are created equal. Manufacturers tend to regard acrylic solid surface as a better product than polyester, as it’s more durable, easier to maintain and easier to fabricate. Likewise, certain colors of solid surfaces are better for certain environments. Here are a few general guidelines on how to choose solid surface colors to best meet your needs.

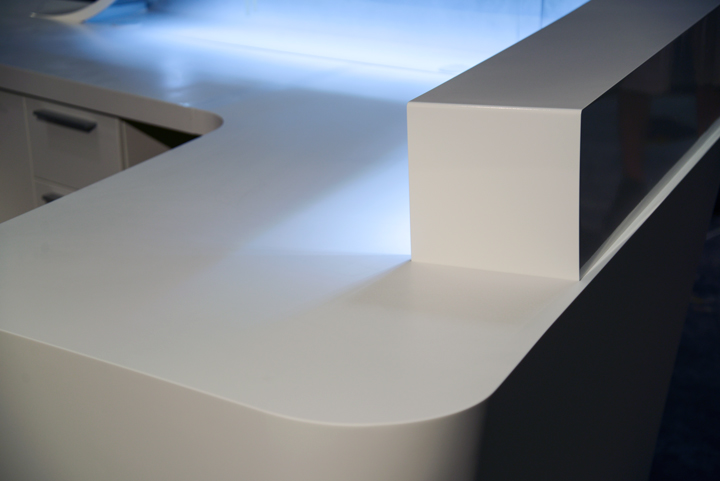

Seams

Seams play a big role in color choice, as least for fabricators. Any time you join two pieces of material, there will be a seam. The seam is chemically welded, smooth to the touch and moisture-blocking, but if not done correctly, it will be visible.

A qualified craftsman will always be able to tell if there is a seam, even when well done. That’s why, as fabricators, we like to see certain colors picked over others. We know that some colors better hide seams, making your product look better and our job a bit easier. Solid white is the best color for making inconspicuous seams. Any solid color other than white can make it more difficult to hide the seams, especially in darker solid colors where there is no particulate to distract your eye away. In terms of hiding seams, then, solid white is the best option, but other colors that have particulates—solid surface chips that give the final products certain patterns or designs—can also sufficiently disguise seams.

Scratches

The dreaded scratches can also affect color selection. A fun fact that most people are not aware of is that solid surface will scratch white, no matter the color. So if you specify a dark color, say black, and scratch it with a knife, it will look like a white scratch. Why is that? It is because of the acrylic that is put into the mix. We require clients to sign waivers when they request certain dark colors acknowledging that such color require additional maintenance. Manufacturers are also beginning to label their samples with little disclaimers, but they often leave it up to us to educate the client, who typically already has his or her mind set on the color by that point. Some manufacturers are working on new darker colors that don’t scratch white, and while these new product don’t scratch as white, you can still see some white.

Therefore, when selecting solid surface colors, you must really consider your environment. What kinds of demands will the product face each day? What is the likelihood that the product will be scratched? If the piece is going in a kitchen where knives are abundant and everyone is moving at triple speed, you might consider a lighter solid surface color. If you’re just adding a sleek new reception desk to your hotel lobby, a darker color might not be quite so perilous. The main thing is to consider all of the possibilities of the environment and make an informed decision.

Time and money

When selecting a color for your solid surface product, you should also consider your own resources. How much time and money are you willing or able to invest in upkeep of your product? Think about the environment the product is going in: Would the workers in that space have much extra time to ensure the products there aren’t getting damaged? Or will product upkeep become a hassle pushed to the side until the piece is damaged beyond repair? To be sure, solid surface is extremely beneficial for its fairly small amount of required upkeep, but, like any product, it will deteriorate without proper care. Taking this into consideration will help you select a color that fits your needs.

Quick tips

It’s important to think realistically about both the conditions of the specific environment and your own resources. How to choose solid surface colors depends on so much more than personal tastes. Here are some general tips to keep in mind when choosing colors:

- The lighter color the easier to maintain

- Colors with particulates make seams more inconspicuous

- Colors not veined or directional also help hide seams

- Dark colors are more easily damaged

- Solid colors or colors low on particulates require more upkeep

- Colors requiring a high gloss finish also often require more upkeep

Sorry, the comment form is closed at this time.