Meet manufacturing 3.0: custom documentation station

There are a lot of articles about what mass customization means to the consumer, but it’s hard to find solid thinking and conversation about these macro-level changes in the manufacturing environment.

Put plainly, we believe manufacturing version 3.0 means you get what you want, cheaper than what an off-the-shelf product costs. It should also be the nicest thing you’ve ever bought.

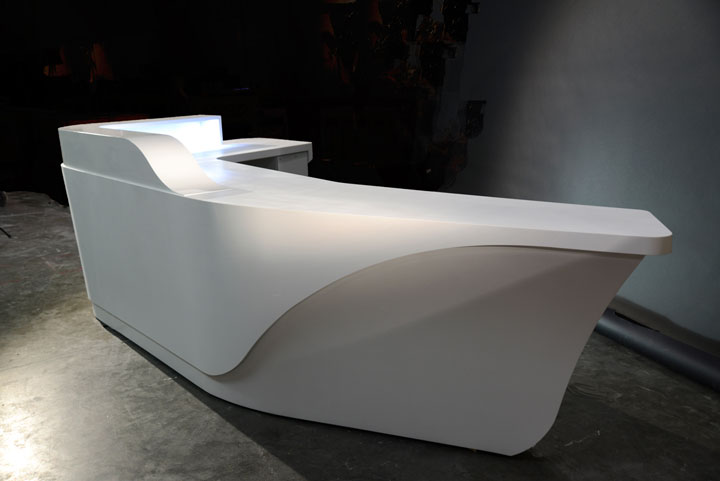

The lower level of this custom solid surface documentation station slides under the upper, allowing ease of use and cleaning, as well as full visibility to the cases in the operating room.

While the rise of manufacturing 3.0 shifts thinking on how to purchase and specify products, it is still theoretical for most people.

Real understanding comes with real implementation. The best way to explore this new model of design and manufacturing is to observe how it works in practice.

Custom documentation station

There is nothing more functionally critical in a hospital than the operating rooms. The people and processes must work seamlessly to make sure that the right care is delivered and communicated. For surgeons, nurses and even technicians, the operating room’s components must function as a seamless extension of each operator’s process.

And that’s where standard operating room furniture gets into trouble. For instance, most off-the-shelf documentation stations face the documenter away from the procedure. The nurse is forced to write or type on his or her lap to record what is happening and then turn 180 degrees to document it.

In this project, the hospital’s design team had a better idea. Instead of having a single-size-fits-all approach, forcing nurses to adapt to the standard, they realized their design should meet their clients where they are.

Design for the future

When designing operating rooms for a new patient tower, the team actually realized they could turn the desk 90 degrees, limiting the rotation needed to face the operating table.

Through extensive user testing and interviews, the design team concluded that sometimes that was enough, but for longer operations, the nurse needed to face the operating table directly. While this is only a portion of the operations, the need is significant, given the time period of longer operating cases.

Focus groups comment on the design of the mock-up space of the operating room, including the custom solid surface documentation station.

That’s where Shield and the idea of Industrial Revolution 3.0 became a reality. The Shield staff took the concept of a rotating desk and worked through the details, testing and specifying the hardware, and applying the product’s high engineering standards.

The end result is a 100-percent solid surface, custom documentation station that is completely nonporous, down to stainless steel hardware. (Even the underside is clad in solid surface for complete protection.)

Equally important, the desk functions just as the staff needs, and was delivered inside of an extremely tight prototype schedule at a lower cost than comparable off-the-shelf products. As a manufacturer, we are also seeing more interest from the design community in building with solid surface, in operating rooms and in other spaces due to the flexibility of the material and the interest in durability.

The pivoting mechanism was a point of special focus for our team, since it was a vital point of function for the desk. Shield’s staff hybridized a few pieces of hardware to create the leg and swivel point, which allows the smooth rotation of the movable piece of the station.

The rise of manufacturing 3.0

The true innovation in manufacturing 3.0 is developing flexible software and hardware solutions. While a particular piece appears to be custom, and in most respects is, the process to create it is actually a standard that can be applied to a myriad of circumstances.

In short, we are in the midst of the greatest industrial revolution since the moving assembly line.

Customization is possible in ways people could never have imagined a decade or two earlier, which makes it a great time to be a designer.

Sorry, the comment form is closed at this time.