Solid Surface vs. Laminate: Which is Better for your Casework?

If you haven’t heard, laminate is history… At least as you know it. Created from a process of compressing layers of paper and resin over a thick glued brown craft paper that is then heated, laminate has been a popular choice within medical furniture for years.

Funding a project is a huge undertaking and finding ways to put your money to use can be a struggle. Functionality and aesthetics shouldn’t have to be a choice, but often are due to budget constraints. That’s where laminate enters the picture.

Though not a long lasting option, the price can be appealing to keep costs at a minimum. However, a low one time cost only means so much if “one time” becomes more.

With heavy usage laminate breaks down, making replacements a regular occurrence. According to the American Society of Healthcare Engineering (ASHE), five characteristics have been found to create long lasting and safe casework. Sadly, laminate does not hold up to any of the five. Fortunately, we have a solution.

What is delamination?

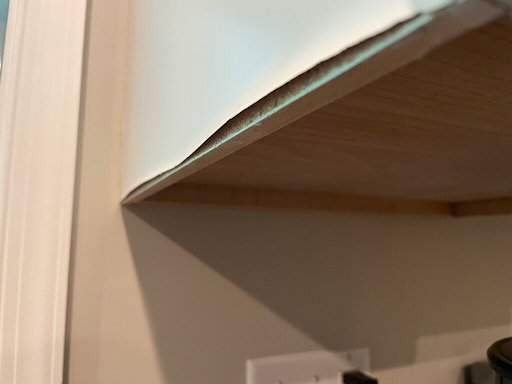

Laminate is not one material, but multiple layers of different materials bonded together. The process of delamination begins when one of the layers becomes damaged, exposing every other layer to the elements.

Most commonly, laminate has four layers; a top layer that is impact resistant, a printed design layer, a high density fiberboard at the core and a bottom balancing layer. While multiple layers sound good in theory, when faced with any kind of damage, the top layer is the only one that offers any protection.

If the top layer fails, the bottom layers then become susceptible to damage which in turn causes the entirety of the material to give out. When your cabinets or medical storage begin to degrade the aesthetics are no longer pleasing and infection control is less likely.

Photo courtesy of Just Add Paint

Why worry?

Hospital casework should be a bastion of safety. Staff are consistently interacting with the equipment and then interacting with patients. In these situations, keeping everyone’s safety in mind means making sure that the materials used for casework will not foster infections or bacterial growth.

As reported by the National Library of Medicine, “Hospital-acquired infections are emerging as important causes of morbidity and mortality in immunocompromised patients and severe underlying illnesses. Each year, 2 million patients suffer from hospital-acquired infections and nearly 100,000 of them die.”

While HAIs have always been a focus in healthcare furniture and design, in more recent years there has been an incredible push for infection control.

Laminate, being a cheap option, is found all over patient rooms. Though the material can look clean, visuals don’t tell the whole story. With multiple middle materials, the surface becomes a breeding ground for bacteria and microbial life to find their forever home.

This hospitality towards bacteria means the lasting power is less than desirable. With middle layers becoming exposed, the product quickly breaks down. Even with minimal damage, time will cause laminate to warp, altering the original look.

“We had been looking for an alternative to plastic laminate and metal casework for use in a hospital setting for several years,” said Mark Hunter, architect at ACI Boland Architects. “Plastic laminate does not hold up well.”

So why worry? We know patient safety is a top priority, and laminate fails when it comes to protection from infection. When highly touched surfaces are created with the base material being laminate, both your patients and staff’s well-being are compromised.

“In a post COVID-19 world, greater emphasis will be placed on the types of materials used on surfaces throughout the spectrum of care. SHIELD’s furniture products are inherently microbial resistant and are the perfect choice to minimize the spread of disease and HAIs in the healthcare environment. Combined with their lifetime warranty and forward looking aesthetic, SHIELD is a good solution for the modern healthcare environment.”

– Lynnette Tedder AAHID, CID, IIDA, EDAC, LEED AP, WELL AP | Healthcare Interiors Practice Leader, Senior Associate | Perkins+Will

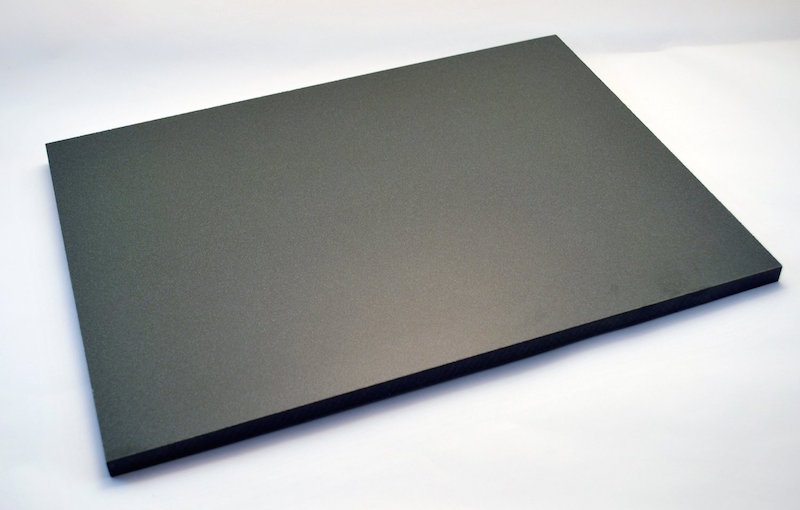

Solid surface: The solution

So if laminate doesn’t work, what does? Composed of aluminum trihydrate (ATH) as the base and polymethyl methacrylate (PMMA) as the bonder, acrylic solid surface is homogenous with no middle material which brings unique benefits to your furniture including;

- Quick & easy cleanability

- Strong durability

- Non-porous finish

- Seamless build

- Microbial resistance

With no middle material solid surface is in fact solid for handling even the worst damage. Instead of wondering if one layer of material will protect your entire storage unit, you can know that spills or impacts can be easily fixed and will not affect the look or usage of the product.

Even when solid surface deals with impacts, resulting damages can be quickly buffed away with a scotch brite pad. This also means that furniture will not harbor bacteria and can be quickly, yet thoroughly cleaned to keep patients, staff and care teams fully protected.

Life in healthcare is hectic and casework will be subjected to impacts. Solid surface promises that no matter what comes its way, it will always keep its intended vision and performance.

Sorry, the comment form is closed at this time.