Headwall Design Assist

So you have to design a headwall... now what?

Headwalls are an absolute mountain to conquer in hospital design. There's med gas connections and electrical layout, on top of workflow configurations, not to mention aesthetics. As an architect, finding time to devote to what is a very small part of hospital design seems impossible. But don't worry, here's how to do it the Shield way:

- Discuss headwall needs needs with clients early

Understanding what use cases and goals a client has with their patient headwalls is paramount in staying on schedule and on budget. Does this client want a basic, utilitarian approach, or something more bespoke? Once a clear design vision is established, it's time to call in the heavy lifters. - Bring in Design-Centric Manufacturers

Like we said above, designing a headwall takes time. Starting conversations with manufacturers sooner rather than later can save a lot of headache and back-and-forth. Manufacturers, like Shield, design custom headwalls for all client types and environments. We have tools and models at our disposal that can take a lot of the guesswork and confusion out of headwall design. - Create initial design

Combining the design vision with the manufacturer's recommendations into an initial model is when headwall design finally begins to take shape. The first review of a custom headwall design is exciting, but it's important to stay focused on details. - Review, revise, rework

Headwall design is highly customized, so it's only natural that a few revisions along the design process are necessary. Keeping the design vision at the front of your mind is important to ensure that any edits made are push the design closer to the intended vision. - Production + Install

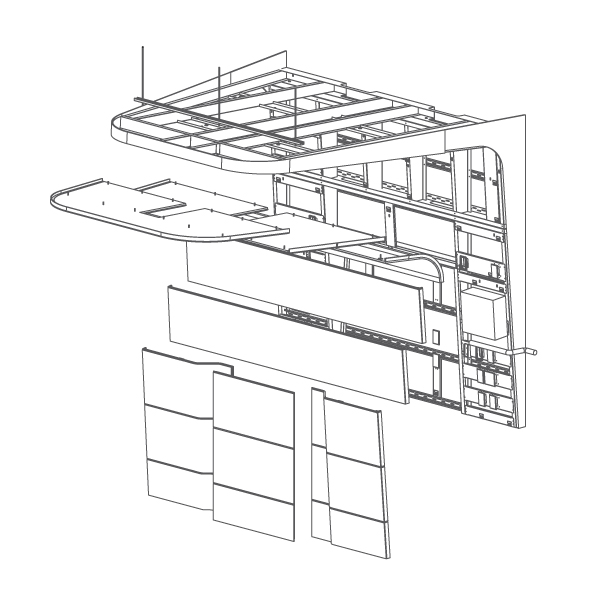

Now the design is approved and it's ready for production. The manufacturer now engineers the design for machine cutting, then it's time for fabrication. The entire design is constructed to make shipping, delivery, and installation as easy as possible. No on-site construction here - modular fabrication makes on-site installation quick and easy.

"Functional and durable is nowadays a given. Partnering with Shield helped us create a one-of-a kind design for a very special client intensely focused on elevating the patient experience."

- Carlos Amato, AIA, ACHA, EDAC, LEED AP

Principal, CannonDesign

Making beautiful objects—objects that people want to have in their space, to live with and look at daily—is the very first step, a baseline or minimum expectation. What makes the product special, more than just a pretty piece of furniture, is when they are shipped sustainably, minimize waste, maximize the customer’s dollar, install quickly, and last forever…that’s Design.

Sorry, the comment form is closed at this time.